Packaging foods in glass

Practical Action

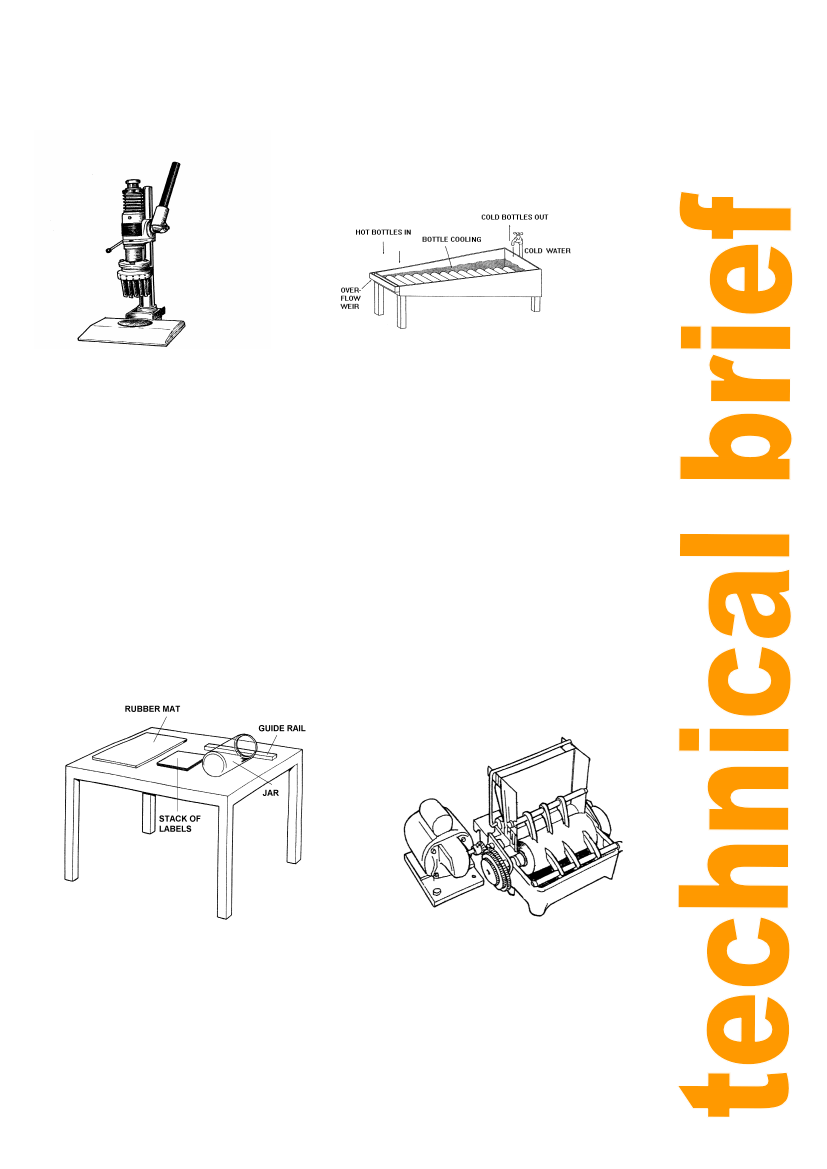

Figure 15: Jar sealer

Figure 16: Bottle cooling equipment

Processing

Some products are heat processed after packing into glass containers. They should be heated

and cooled gently in order to avoid breaking the glass. One method of controlled cooling of

containers after processing is shown in Figure (16). Cold water enters at the deep end of the

trough and overflows at the shallow end. Hot bottles are placed in at the shallow end and roll

down to the deep end. The temperature is cool at the deep end and gets hotter along the

trough, so minimising the shock to the hot containers.

Labelling

Paper labels are the most common type used on glass containers. They can be plain paper

that is glued onto the glass or alternatively self-adhesive types. Figure 17 shows a simple

frame which can be used to hold plain labels, wipe glue over top of label in stack, roll jar

along guide rail over label, roll and press jar and label into rubber mat. Small labelling

machines (Figure 18) can be used to apply strips of glue to labels. A typical powered labeller

has an output of about 40 labels per minute.

Figure 17: Labelling table

Figure 18: Small labelling machine

Water soluble glues such as starch or cellulose based glues are best if containers are

returnable, so that labels can be easily removed. However, these glues may loose adhesion in

humid climates. Non water-soluble glues, based on plastic polymers, are available and

advice on the correct type should be sought from the suppliers.

6